Outlook: Growth market Honeycomb technology

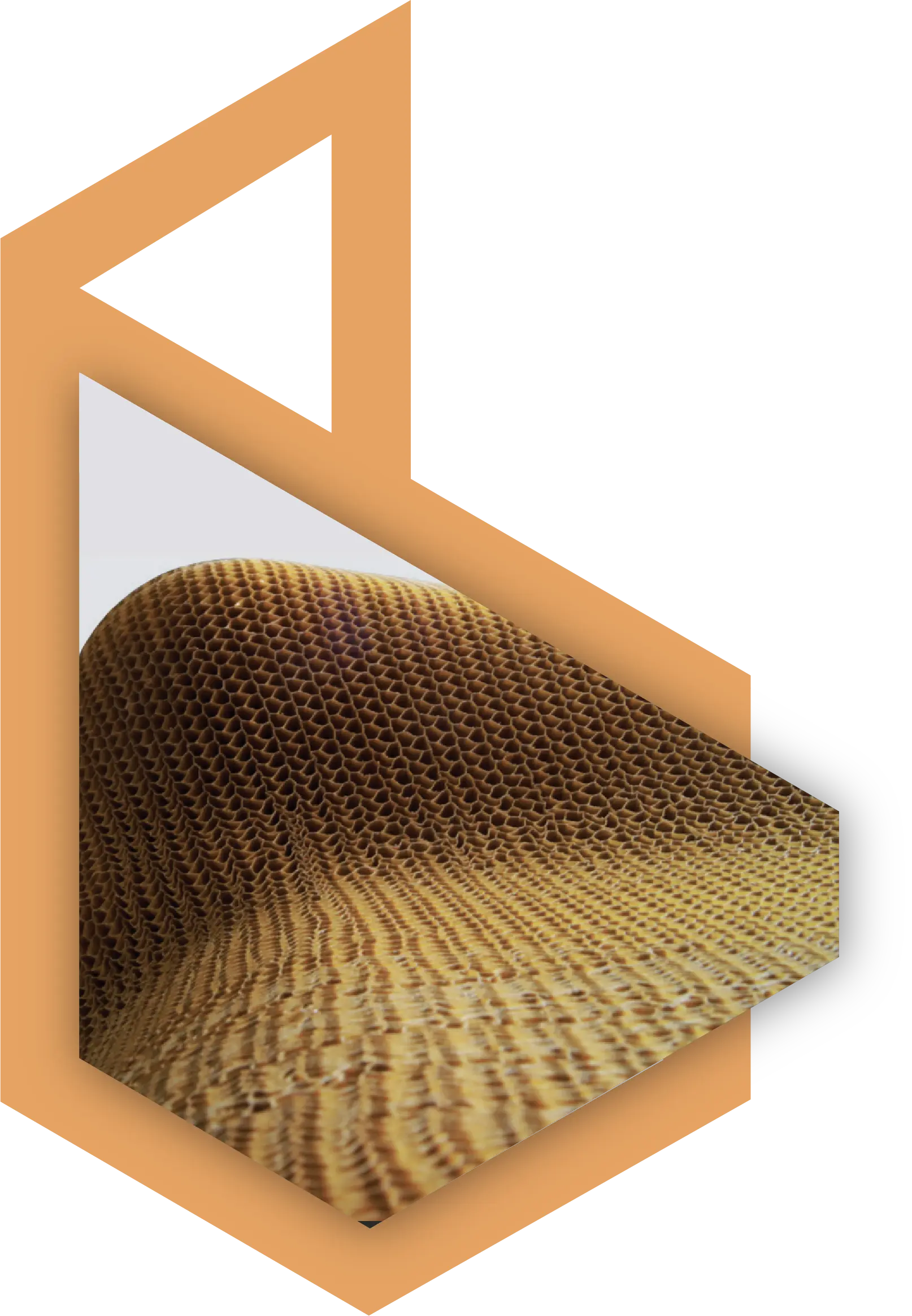

Packaging technologies are not the only future market in which IB is driving innovation. A revolution in various industries in the field of honeycomb technology is currently in preparation.

Honeycomb technology is a process that enables the construction of extremely strong and durable structures using recycled waste paper as a base material. In principle, this is a bionic technology, since the construction of the honeycomb construction is based on that of honeycombs.

The honeycomb technology is causing a revolution in container construction: The paper-based honeycomb can withstand an almost unimaginable load of 33 tons per 100 square centimeters (10 cm x 10 cm). It is thus possible to produce extremely stable and resistant rail and ship containers that are lighter than all previous alternatives and are therefore considerably cheaper to transport and also to manufacture.

Revolution in Shipping and other Industries

One of the most exciting areas of application for honeycomb technology is container construction, especially for shipping.

The worldwide demand for sea containers in particular is enormous: 90 percent of global goods traffic is transported by ship. But the container technologies are comparatively backward: For the 30 million freight containers that are in use worldwide, 30 million square meters of tropical hardwood are harvested annually for new construction and maintenance.

Commodity markets are picking up all over the world: shortages and rising prices are evident not only for wood, but for practically all commodities that can be used to build containers, airplanes and houses.

But a sustainable alternative is in sight, because honeycomb technology based on recycled paper is also an optimal building material here. Top layers such as paint, plastic laminations, wood veneers can be applied to the paper honeycomb, which is hardened using chemical processing and other additional layers can be applied. When several layers of paper honeycomb are combined in the so-called sandwich process, the strength can be increased by a factor of 2.5.

Superior Material properties

On the one hand, chemical and physical properties, such as heat resistance and fire resistance, water resistance or water repellency through beading, can be achieved. On the other hand, the appearance of the material can also be adapted exactly to customer requirements.

With the various available combinations of honeycomb technology with coatings, materials and top layers, stability with the lowest weight can be achieved with the inexpensive paper honeycomb, which is otherwise only offered by aluminum or NOMEX honeycomb from aircraft construction For example, a weight reduction of 450 kilograms can be achieved with a semi-trailer in sandwich construction.

The tables show a comparison between IB paper honeycomb and conventional alternative construction materials. The compressive strength of IB paper honeycomb is significantly superior to both conventional paper honeycomb and other honeycomb technologies.

| MANUFACTURER | MATERIAL | COMPRESSIVE STRENGTH (kPa) |

|---|---|---|

| Paper honeycomb | Paper | 550 |

| Aramid honeycomb | Nomex | 600 |

| Metawell | Aluminium | 2.000 |

| Wacotech | PET | 650 |

| Plascore | Polypropylen | 1.620 |

| MANUFACTURER | MATERIAL | TESTING STRENGTH (mm) | COMPRESSIVE STRENGTH (kPa) |

|---|---|---|---|

|

Honeycomb 4 | 12 | 5.200 |

| Honeycomb 5 | 12 | 6.000 | |

| Honeycomb 6 | 12 | 6.400 | |

| Honeycomb 7 | 12 | 7.600 | |

| Honeycomb 8 | 12 | 8.800 |

The table below illustrates how IB paper honeycomb compares to other materials on various relevant factors:

| PRODUCT | STABILITY | LIGHTNESS | ENVIRONMENTAL FRIENDLINESS | LOW COST | AVAILABILITY OF RESOURCES |

|---|---|---|---|---|---|

| Steel | |||||

| Tropical wood | |||||

| Other hardwood | |||||

| Aluminum honeycomb | |||||

| Hard foam | |||||

| Paper honeycomb | |||||

| IB honeycomb |

IB has not only invested in research and development work and successfully brought it to market, but also established powerful and quickly scalable production processes.

The continuous production of the paper honeycomb is possible at 4 to 8 meters per minute with a throughput width of 2.80 meters. The production system has a modular structure so that changes to the specifications by the customer can be implemented quickly and cost-effectively be able.

The entire production process is in the hands of IB, which offers the customer maximum flexibility and control over the parameters of the resulting product.